Kamensk-Uralsky Metallurgical Plant JSC is a successful company with a well-known brand name in Russia and around the world, a high business reputation, and more than 80 years of history and development. It is a diversified enterprise specializing in the production and supply of products for the aviation and shipbuilding industries, mechanical engineering, the energy sector, and other sectors of the economy. It is a leader in the federal ranking of Russian aluminum rolling manufacturers

39

42

43

44

45

51

58

59

63

70

72

78

82

92

93

98

07

15

19

24

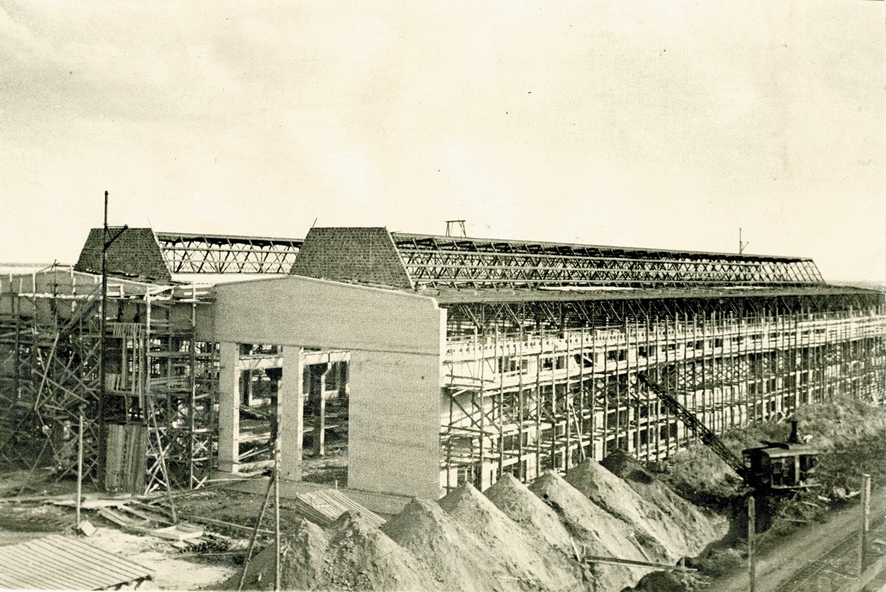

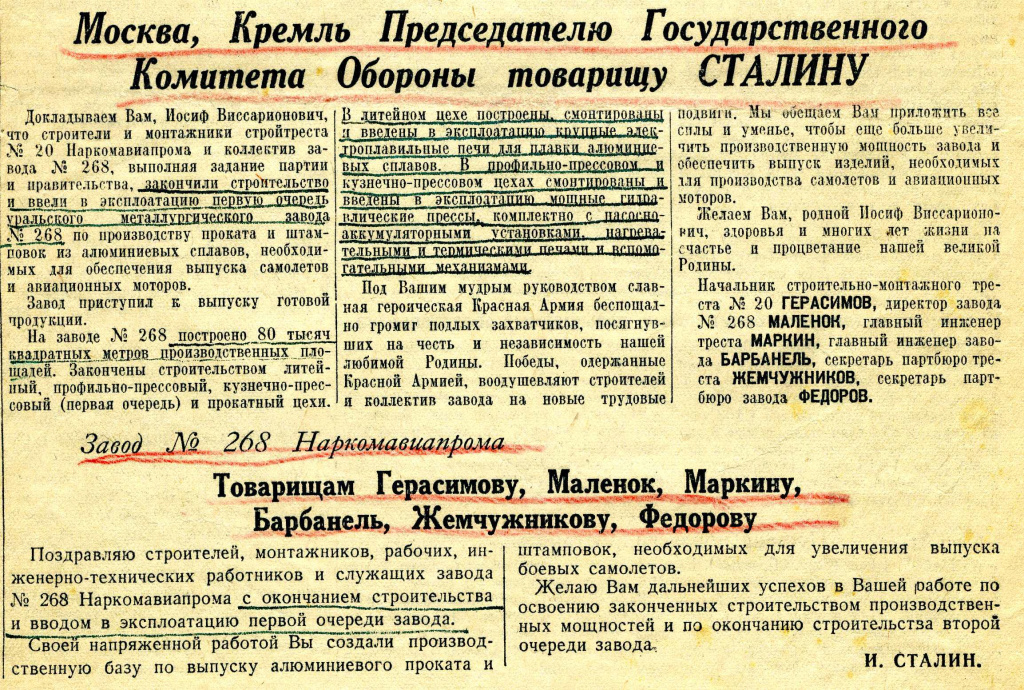

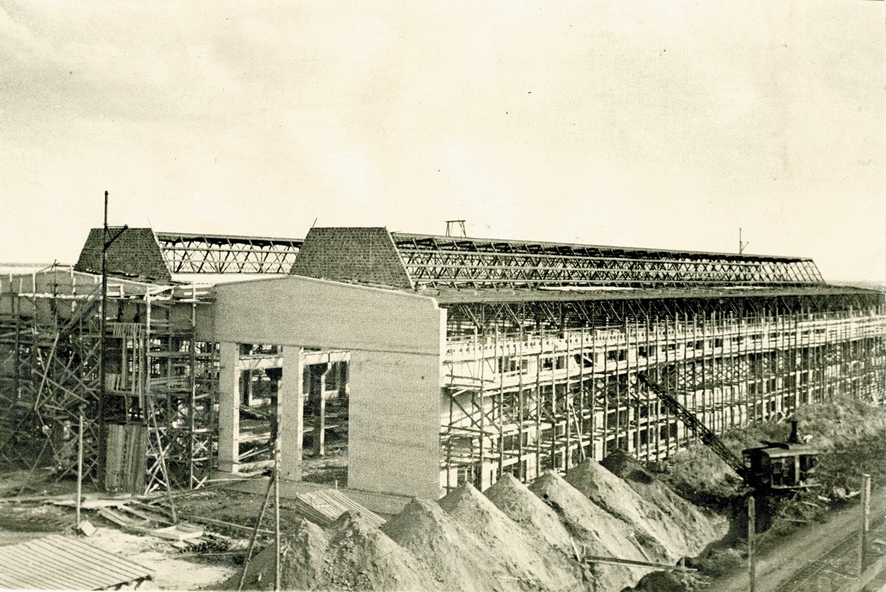

The 3rd of June. Resolution of the USSR Economic Council No. 513-99c on the construction of plant No. 268 (KUMZ).

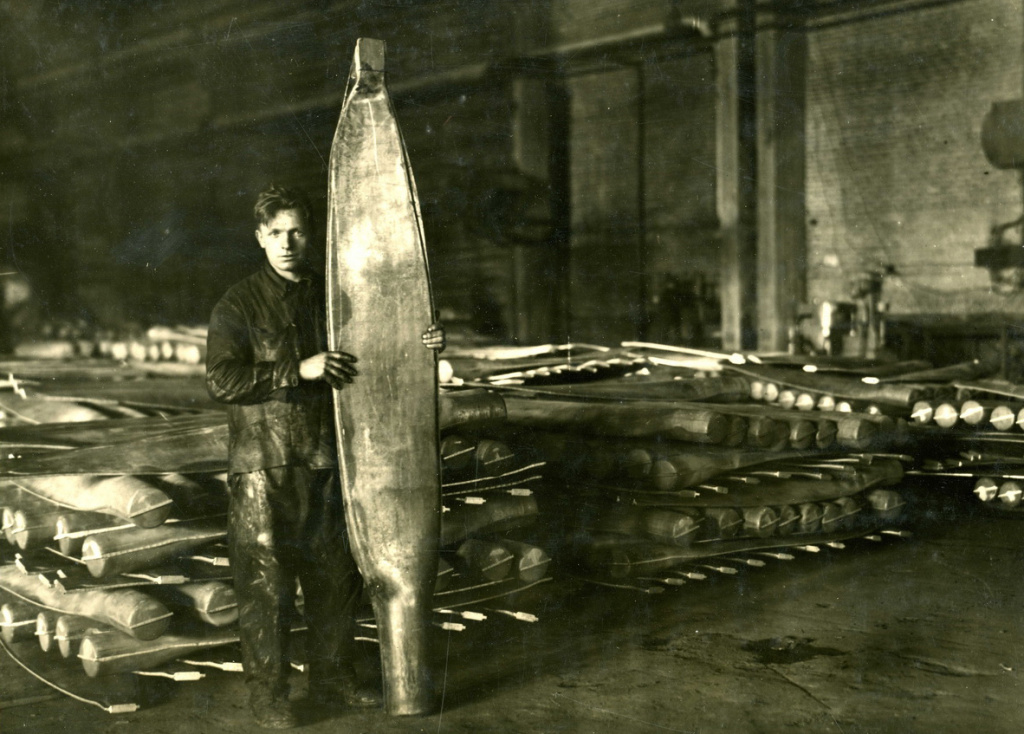

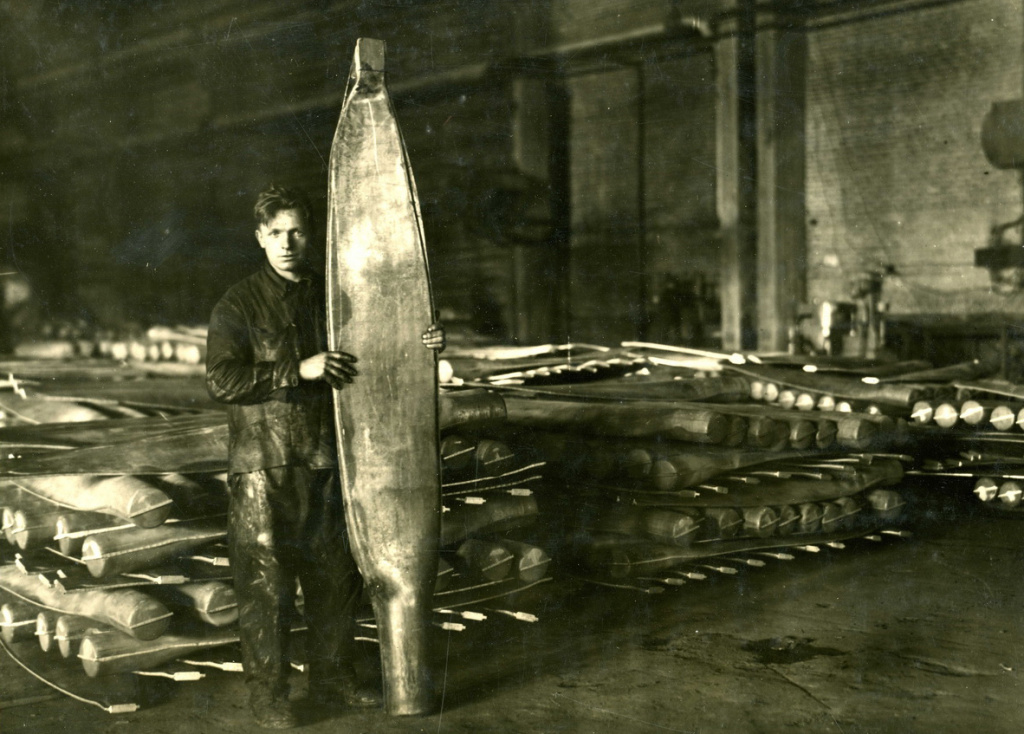

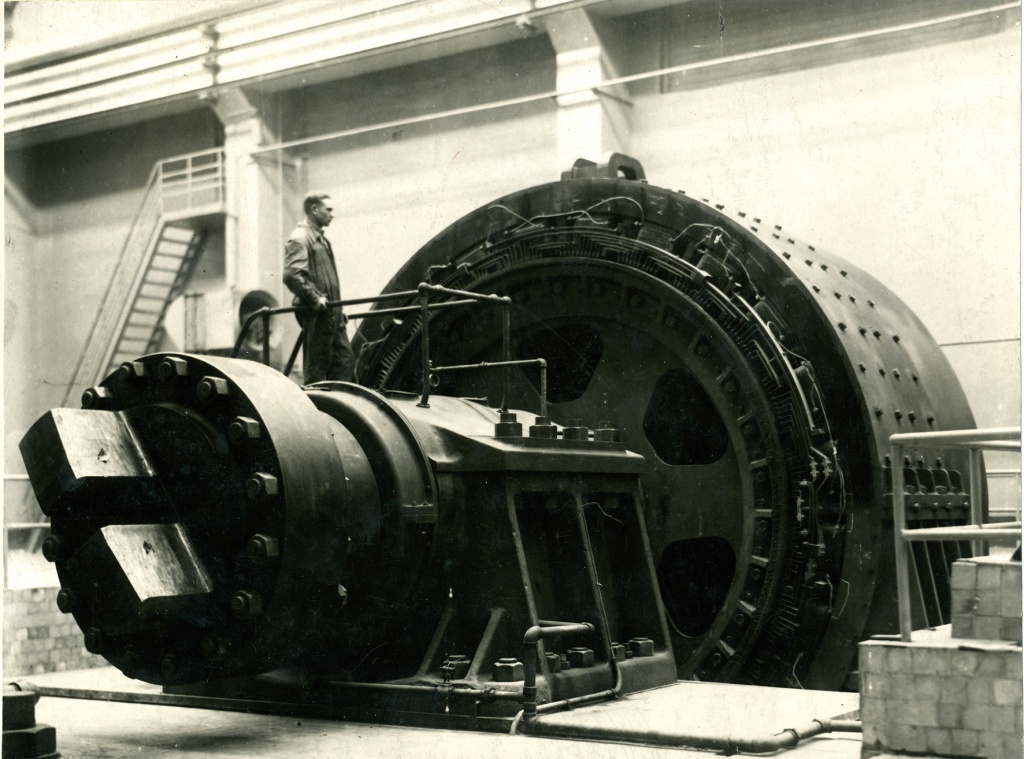

The 14th of February. The first metal was obtained, and the first ingots were cast.

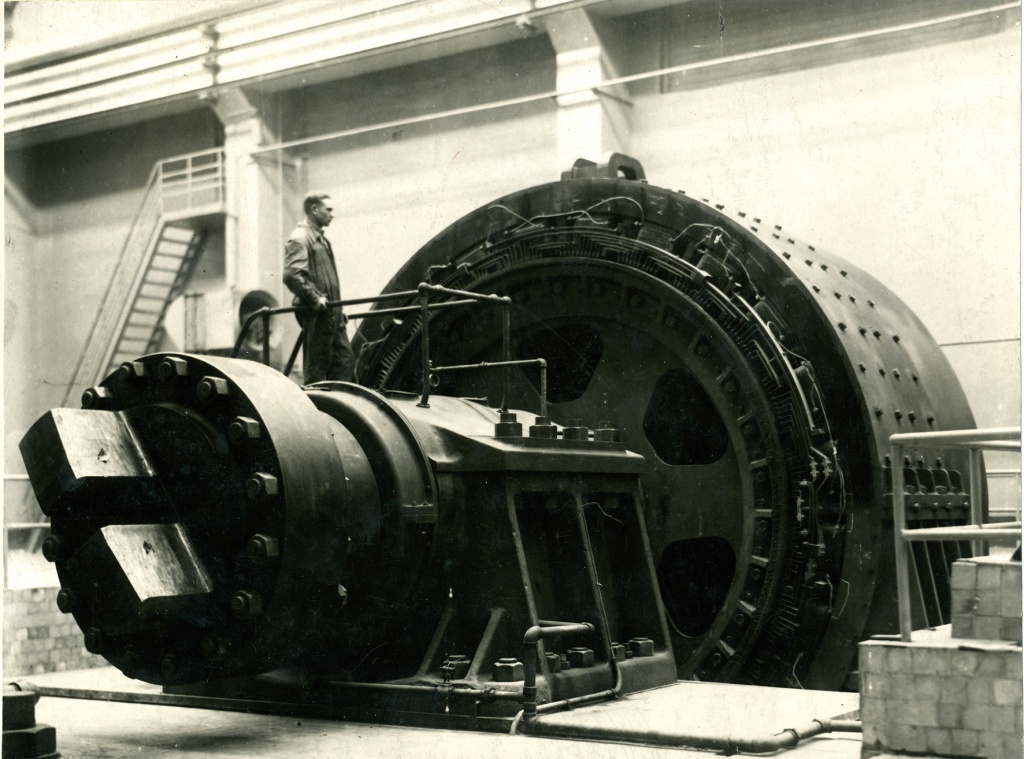

September 1st. The casting workshop has been put into operation.

November 7th. The extrusion workshop has been put into operation.

January 1st. By order of the NKAP, plant No. 268 was formed into an independent business unit.

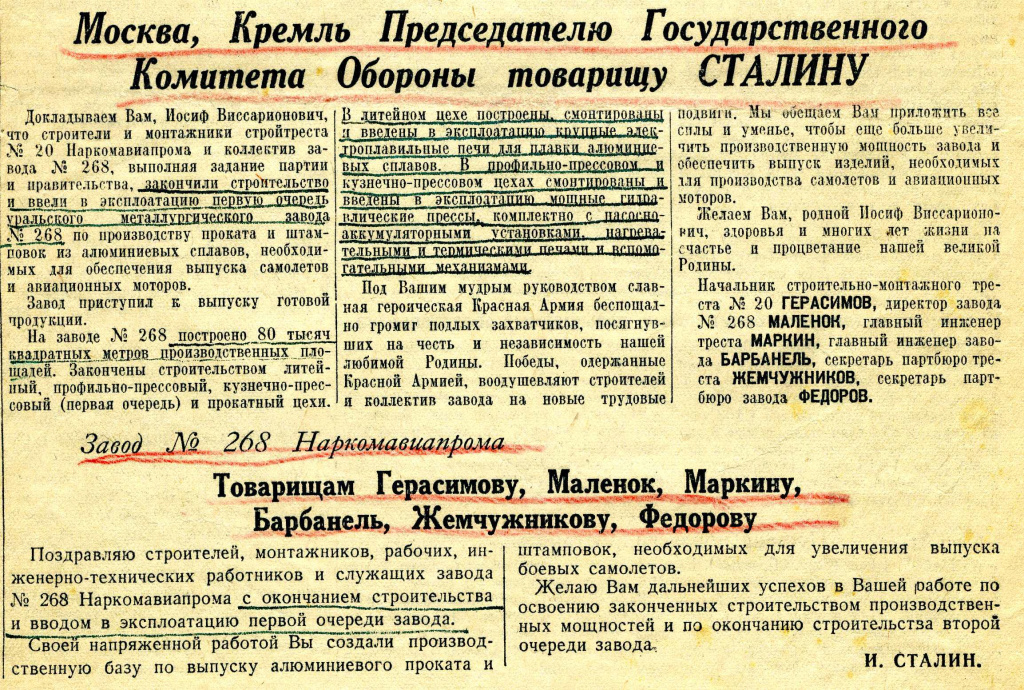

May 5th. The first stage of the plant was put into operation.

April 7th. The release of the first sheet products.

May 29th. The decision of the State Commission on the commissioning of the entire factory complex (the order on NKAP dated 06/11/1945).

September 16th. 58 factory workers were awarded orders and medals for their exemplary performance of government tasks.

September 14th. A forging and extrusion workshop 6 building has been put into operation for the production of large-sized die-forgings and profiles.

December 31st. A new casting workshop building 36 was put into operation.

December 28th. A new extrusion workshop, building 85, has been put into operation.

The 21st of April. A group of factory workers became Lenin Prize laureates.

December 10th. A radial rolling complex for rolling out ring blanks has been put into operation.

April 24th. The first drill pipe has been produced in the new piping workshop.

June 8th. By decree of the Presidium of the Supreme Soviet of the USSR, KUMZ was awarded the Order of the Red Banner of Labor.

June 16. A new line for the production of non-stick cookware has been commissioned.

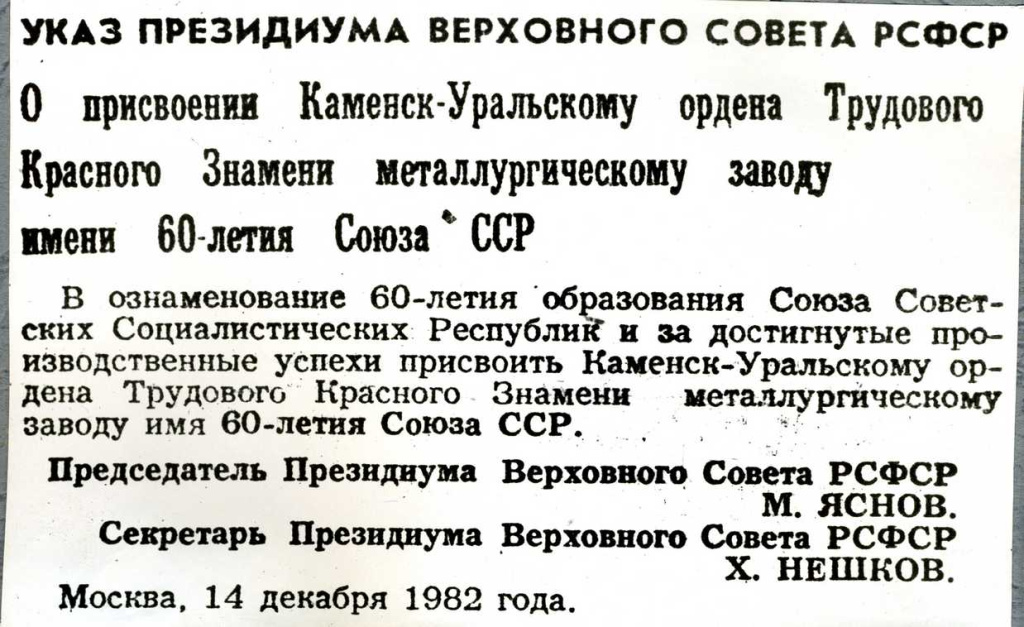

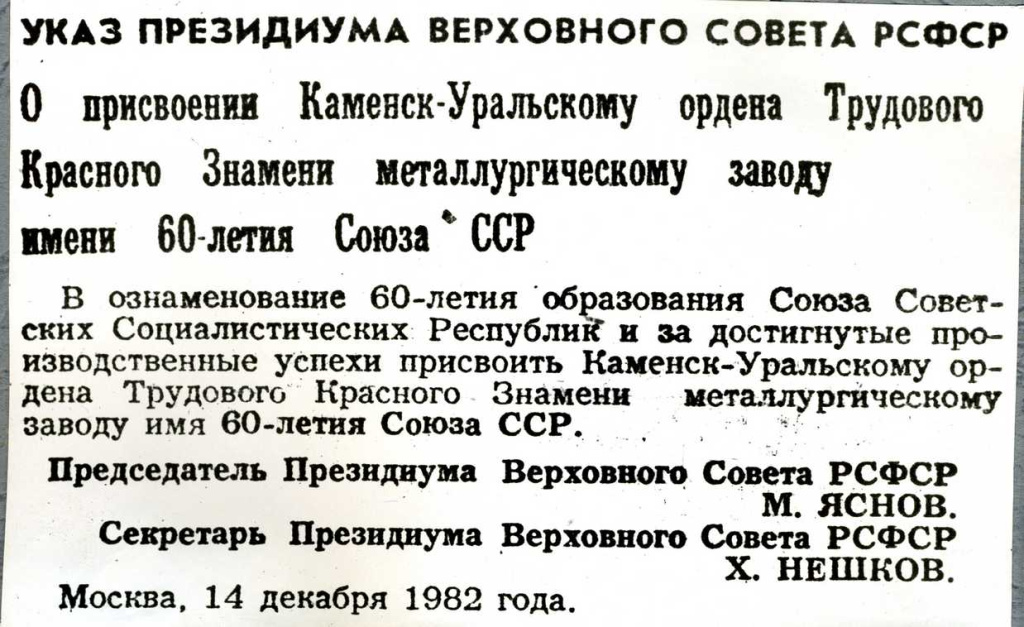

December 14th. Decree of the Presidium of the Supreme Soviet of the RSFSR on awarding KUMZ the name of the 60th anniversary of the USSR.

November 30th. The plant has been reorganized into an Open joint-stock company.

February 23. A new line for the production of heat exchangers for household refrigerators has been commissioned.

November 27th. The first meeting of shareholders of KUMZ JSC was held.

In July. The factory quality system was certified for compliance with the requirements of the international standard ISO 9001.

December 12th. A new production facility for the thermomechanical processing of plate products (the Chkalovsky plant) has been commissioned.

19th of May. The production facilities of the first stage of the New Rolling Complex were put into operation.

August 18. A solemn presentation of a New rolling complex (stages I and II), which produces aluminium alloy products with new unique characteristics using modern equipment.

August the 8th. As part of Innoprom 2024, KUMZ signed a long-term Strategic Partnership Agreement with UAC.

KUMZ turned 80. The company is the leader of the federal rating among Russian manufacturers of aluminum products. No. 1 in terms of technological equipment among enterprises in the deep aluminum processing sector in Russia and Europe.

The 3rd of June. Resolution of the USSR Economic Council No. 513-99c on the construction of plant No. 268 (KUMZ).

The 14th of February. The first metal was obtained, and the first ingots were cast.

September 1st. The casting workshop has been put into operation.

November 7th. The extrusion workshop has been put into operation.

January 1st. By order of the NKAP, plant No. 268 was formed into an independent business unit.

May 5th. The first stage of the plant was put into operation.

April 7th. The release of the first sheet products.

May 29th. The decision of the State Commission on the commissioning of the entire factory complex (the order on NKAP dated 06/11/1945).

September 16th. 58 factory workers were awarded orders and medals for their exemplary performance of government tasks.

September 14th. A forging and extrusion workshop 6 building has been put into operation for the production of large-sized die-forgings and profiles.

December 31st. A new casting workshop building 36 was put into operation.

December 28th. A new extrusion workshop, building 85, has been put into operation.

The 21st of April. A group of factory workers became Lenin Prize laureates.

December 10th. A radial rolling complex for rolling out ring blanks has been put into operation.

April 24th. The first drill pipe has been produced in the new piping workshop.

June 8th. By decree of the Presidium of the Supreme Soviet of the USSR, KUMZ was awarded the Order of the Red Banner of Labor.

June 16. A new line for the production of non-stick cookware has been commissioned.

December 14th. Decree of the Presidium of the Supreme Soviet of the RSFSR on awarding KUMZ the name of the 60th anniversary of the USSR.

November 30th. The plant has been reorganized into an Open joint-stock company.

February 23. A new line for the production of heat exchangers for household refrigerators has been commissioned.

November 27th. The first meeting of shareholders of KUMZ JSC was held.

In July. The factory quality system was certified for compliance with the requirements of the international standard ISO 9001.

December 12th. A new production facility for the thermomechanical processing of plate products (the Chkalovsky plant) has been commissioned.

19th of May. The production facilities of the first stage of the New Rolling Complex were put into operation.

August 18. A solemn presentation of a New rolling complex (stages I and II), which produces aluminium alloy products with new unique characteristics using modern equipment.

August the 8th. As part of Innoprom 2024, KUMZ signed a long-term Strategic Partnership Agreement with UAC.

KUMZ turned 80. The company is the leader of the federal rating among Russian manufacturers of aluminum products. No. 1 in terms of technological equipment among enterprises in the deep aluminum processing sector in Russia and Europe.